In the packaging color printing industry, "efficiency" is the core competitiveness for enterprises to seize the market, and "breakpoints" in the production process often become the key bottleneck restricting efficiency. For manufacturers who use small batch digital color printers, the traditional machine's standard small roll paper design has plagued the demand for mass production - even if the roll paper diameter can reach 40cm, in long-term continuous printing scenarios, it takes less than half a day or even less to stop and change paper, which not only interrupts the stable production rhythm, but also increases the time cost and risk of misoperation due to frequent manual operations, making "mass production" become "intermittent small order splicing".

To thoroughly address the pain points in this industry, we conducted in-depth research and analysis on the actual production needs of packaging color printing factories. After multiple rounds of technical research and testing, we have launched a large mother roll feeding rack specially adapted for small batch digital color printing machines, which improves production efficiency from the "source" and makes long-term and large-scale stable printing a reality.

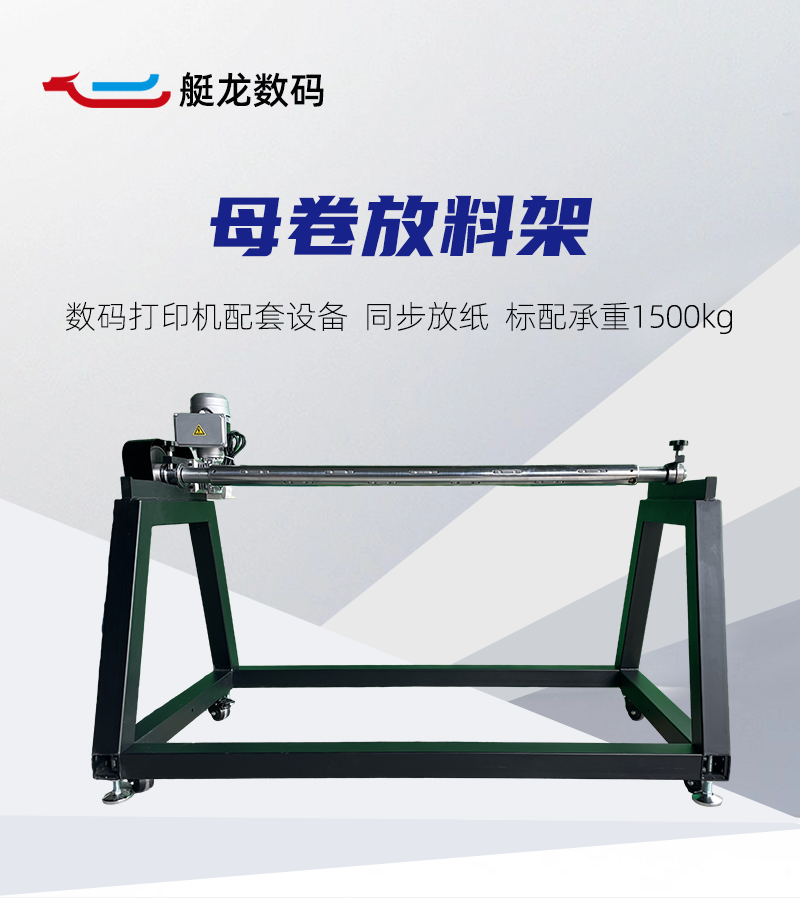

1.5 tons of load-bearing capacity, say goodbye to the trouble of frequent paper changes

The "capacity gap" of traditional small roll paper is the primary issue that restricts production efficiency. Our large mother roll feeding rack has achieved a qualitative breakthrough in load-bearing design - it can carry up to 1.5 tons of large mother roll paper, which is tens of times more capacity per roll compared to traditional 40cm diameter small roll paper. What does this mean? For orders that require continuous printing of packaging materials for several kilometers, frequent shutdowns may have been necessary in the past to replace small rolls of paper. Now, the entire batch production can be completed with just one loading.

Whether it is common packaging categories such as food packaging, e-commerce express bags, gift box outsourcing, or printing substrates such as copperplate paper, white cardboard, gray background white, kraft paper, etc. with different weights, the large mother roll material rack can stably carry them, completely eliminating production interruptions caused by "insufficient roll paper capacity", keeping the equipment in efficient operation at all times, greatly reducing the time consumption and waiting cost of manual paper replacement.

Synchronized and stable feeding to ensure printing accuracy and quality

Mass production should not only be "fast", but also "stable". Once there is a deviation in the feeding process, it can result in paper waste or even printing misalignment of the entire batch of orders, causing huge losses. Our large mother roll feeding rack adopts a synchronous linkage design on the feeding system. Through precise transmission structure and intelligent tension control technology, it ensures that the mother roll paper is completely synchronized with the printing rhythm of the digital color printer during the feeding process, with uniform feeding speed and stable tension, avoiding problems such as wrinkles, offset, and stretching deformation of the paper. Ensure that the color, pattern, and cutting position of each meter of printing material are precise and error free, giving packaging color printing factories more confidence when undertaking high demand bulk orders, without worrying about product quality and customer reputation being affected by feeding issues.

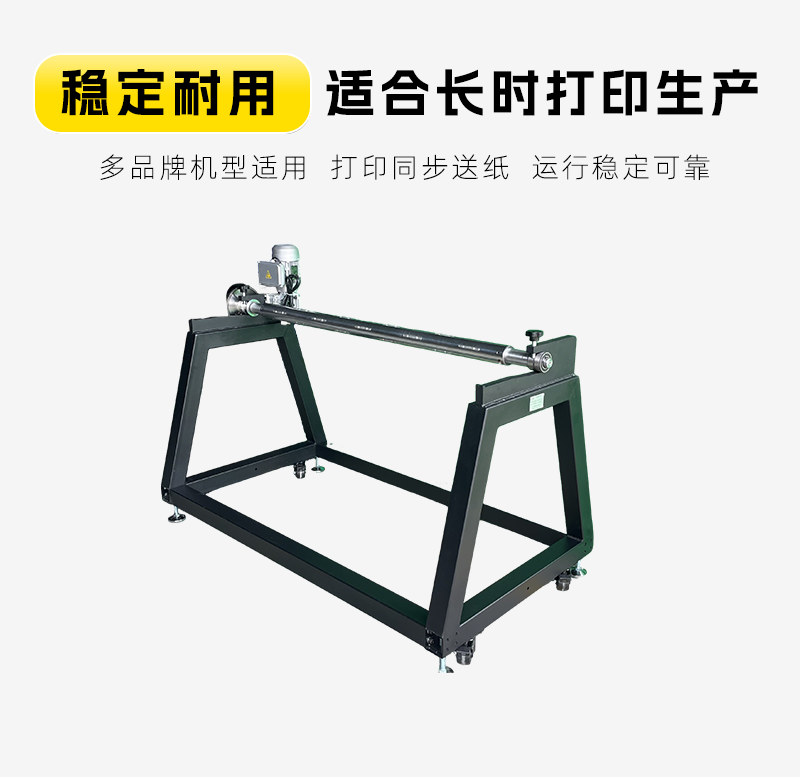

Accurate adaptation to universal roll to roll color printing machines on the market, regardless of brand or model

For packaging color printing factories, the adaptability of equipment directly determines whether they can quickly integrate into the existing production system. Our large mother roll feeding rack was designed with compatibility in mind from the beginning. This supporting equipment can be used universally for all roll to roll scanning digital color printers on the market. There is no need for large-scale renovation of the existing small batch digital color printing machines. With simple wiring and debugging, they can be quickly installed and used, reducing the threshold and cost of equipment upgrades. Whether it is expanding mass production business for small and medium-sized color printing factories or optimizing the efficiency of existing production lines for large manufacturers, the large mother roll feeding rack can be seamlessly adapted.

Small batch stable production, you only need one mother roll material rack. In the increasingly competitive packaging color printing industry, whoever can solve production pain points and improve efficiency will have the advantage. Our large mother roll feeding rack breaks capacity limitations with high load-bearing capacity, ensures quality with synchronized and stable feeding, and reduces upgrade costs with high adaptability, endowing small batch digital color printing machines with core capabilities for mass production.

If your factory is still struggling with frequent paper changes and missing out on large orders due to low production efficiency, you may want to try this large mother roll feeding rack - it is not only an equipment accessory, but also an efficiency tool that helps you increase production capacity, reduce costs, and enhance competitiveness. Let the digital color printing machine bid farewell to small troubles and embark on a new era of stable and efficient mass production!