In the packaging color printing industry, the purpose of pre press sampling is to produce samples that are highly close to the final printing effect, which is a very important part for printing factories to win customer trust. The core purpose of this stage is to comprehensively verify and confirm the accuracy of the design scheme. Meanwhile, customers' demand for personalized packaging is increasing day by day. Sample making needs to meet the unique design requirements of different customers, including unique shapes, patterns, color combinations, etc. For example, some high-end cosmetics brands often have unique designs and exquisite patterns on their packaging, and when making samples, it is necessary to accurately reproduce these design details.

Single head high-precision pre press proofing machine

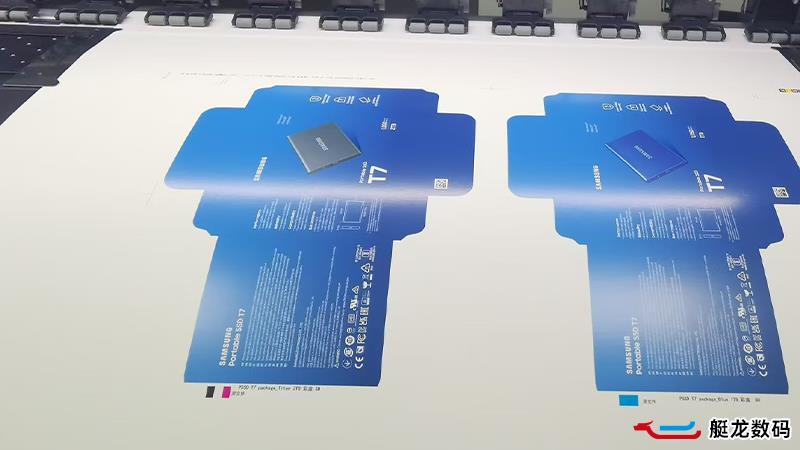

Our single head high-precision digital printing machine is designed to quickly implement pre press sampling. Using a single Epson i3200 piezoelectric head, it can meet the requirements of high-resolution printing and achieve delicate and clear printing effects. Epson's micro piezoelectric technology eliminates the need for heating during ink droplet ejection, thereby maintaining high-frequency stability and further improving printing speed.

Due to the fact that sampling is usually done in small batches, customers are more sensitive to costs. Packaging printing factories need to control costs reasonably while ensuring sample quality, in order to avoid losing customers due to high costs. For example, selecting appropriate printing processes and materials can reduce costs while meeting design requirements. Customers facing such demands often seek a balance between cost control and effectiveness presentation. If the offset printing method is used, the cost issue will be more prominent. This is because offset printing involves multiple costs such as start-up fees and plate making fees, which significantly increase the overall cost. Moreover, pre press proofing is mostly done for small batch customized printing, with scattered orders and limited quantities. If the cost is too high, customers are likely to abandon their printing plans. For packaging and printing factories, if they cannot provide effective solutions, they are highly likely to miss out on these individual customers.

During the sampling process, there may be multiple modifications and adjustments, so it is necessary to minimize the waste of materials and time as much as possible. The use of digital proofing technology can quickly modify design files and reduce the number of plate making and printing processes. It does not require a plate making process and can achieve efficient sample production, reflecting high flexibility and convenience.