In the field of packaging printing, color boxes serve as the core carrier for product display and protection, and their production efficiency and quality directly affect market competitiveness. Traditional printing techniques are constrained by factors such as long plate cycles and material limitations, making it difficult to meet the rapid response needs of modern markets for small batch and personalized orders. The emergence of small digital printing machines, with their technological innovation advantages, is reshaping the production mode of color boxes and bringing significant changes to the industry.

Flexible production capacity that breaks through traditional constraints

Traditional printing requires complex processes such as plate making, color grading, and trial printing, with a single plate making cost of several hundred yuan, and changing designs requires a new plate making process. Small digital printing machines use digital file direct transfer technology to achieve an instant production mode of "instant printing". For personalized orders, it only takes 12 hours from design draft confirmation to the delivery of the first batch of finished products, which is more than 70% shorter than traditional processes. This flexibility enables companies to quickly respond to market trends and seize the opportunity to launch new products.

Customized production that accurately matches personalized needs

The differentiated demand for product packaging in the modern consumer market is increasingly prominent. The small digital printing machine supports variable data printing technology and can achieve independent content customization for each package. For example, customizing an exclusive birthday gift box with personalized greetings and product codes printed on the box surface can increase customer satisfaction. In the food industry, using digital printing to achieve rapid iteration of daily limited edition packaging can also effectively stimulate consumption frequency. This' one box, one design 'capability provides technical support for brands to build differentiated competitive advantages.

The Art of Dynamic Balance between Cost and Benefit

From a cost-benefit perspective, digital printers have also demonstrated significant advantages in small-scale production. Taking 500 color box orders as an example, traditional processes need to bear fixed costs such as plate making fees and color matching fees of about 1500 yuan, while digital printing only needs to pay for material and energy consumption fees. Small batch orders avoid the risk of inventory backlog, and customized printing according to demand and quantity is also accepted by customers, enabling enterprises to more accurately control capital occupation.

Sustainable Practice of Green Printing

The traditional printing process generates a large amount of waste liquid and plates containing heavy metals every year, with high processing costs and environmental risks. Small digital printing machines use water-based ink and on-demand ink supply systems to achieve extremely low waste ink emissions and low-energy operation. This green production model not only conforms to policy guidance, but also becomes an important carrier for enterprises to fulfill their social responsibilities.

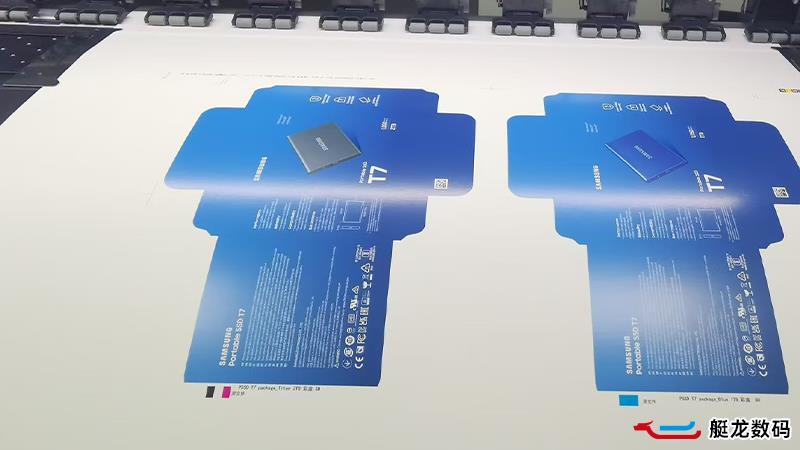

Technological breakthroughs in quality improvement

Digital printing achieves imaging accuracy of 720x1800dpi or higher through high-precision nozzles and color management systems, fully meeting the needs of packaging color boxes. The improvement of packaging quality enables brands to adopt more complex design elements, enhancing the visual appeal of products.

Diversified expansion of industry applications

The technical characteristics of small digital printing machines enable them to demonstrate unique value in multiple segmented fields. In the pharmaceutical industry, a certain pharmaceutical company achieves real-time printing of drug supervision codes through digital printing, ensuring traceability of each box of drugs; In the gift industry, a certain cultural and creative brand utilizes curved printing technology to achieve 360 degree panoramic patterns on irregular packaging; In the fast-moving consumer goods field, a certain beverage brand achieved real-time packaging updates for promotional activities through digital printing, which increased the response speed of promotions by three times.

Against the backdrop of upgrading the packaging printing industry, small digital printing machines are restructuring the production logic of the industry with their technological integration advantages. From production efficiency to cost control, from design freedom to environmental performance, its technological value has been validated by the market. With the continuous breakthroughs in nozzle technology and ink research and development, digital printing will occupy a more core position in the packaging field and become a key force in promoting high-quality development of the industry. For packaging companies seeking transformation and upgrading, grasping the trend of digital printing technology will be a strategic choice for building future competitiveness.