In the current market environment, various personalized printing demands are constantly emerging, such as small batch customized printing services, printing production for scattered orders and supplements, and the need to present diversified packaging printing versions for the same product. All of these urgently require an efficient and fast printing solution. Digital inkjet printing equipment, with its significant advantages of not requiring plate making and supporting single piece printing, can accurately meet these diverse market demands. Therefore, the importance of small batch customized printing equipment is increasingly prominent, becoming a key force in promoting innovative development in the printing industry.

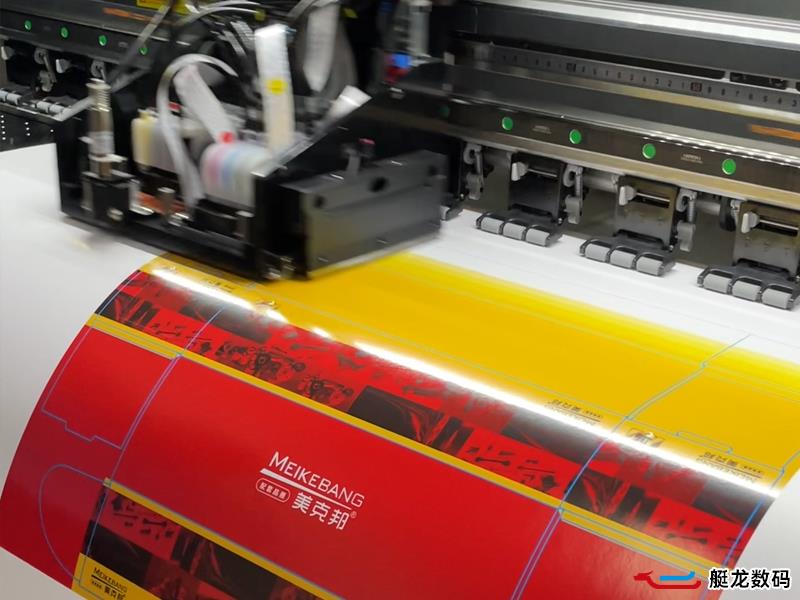

Our 4 head digital printer is specially designed for the printing needs of color boxes with a certain order quantity. Roll paper is used to print various media such as copperplate paper, white cardboard, kraft paper, packaging paper, etc. Import pictures to print, meeting the rapid production of products ranging from a few to hundreds, and flexible production with fast delivery.

Compared to traditional printing, using digital printing can improve order response speed and deliver faster. Optimize overall costs in terms of time and manpower; It can also undertake more high-end cosmetics and electronic product packaging orders through fast printing capabilities, helping enterprises expand their business and increase revenue.

In business competition, digital printing demonstrates its advantages over traditional printing, especially in terms of significantly improving order response speed. The traditional printing process is cumbersome and involves steps such as plate making and color matching. On average, it takes 5 days for an order to be placed and delivered, which can lead to customer loss and missed market opportunities. Digital printing is completely different. It does not require plate making and can directly transmit electronic file information to devices for instant printing with advanced digital technology, greatly reducing the production cycle to one day. This not only enables enterprises to meet urgent customer needs faster and enhance market competitiveness, but also achieves remarkable results in cost optimization. Shortening the production cycle reduces capital occupation and improves turnover efficiency; The high degree of automation reduces reliance on manual labor, reduces manpower input, and overall costs can be lowered.

Digital printing, with its fast printing capability, can easily achieve small batch and multi variety printing, meeting the high requirements of high-end cosmetics and electronic product packaging customers for personalization and timeliness, helping enterprises to undertake more such orders, expand business, and achieve revenue growth.

| Technical Specifications | |

|---|---|

| Machine model | 4 heads digital printing machine |

| Print speed | 4 colors: 30~50 square meters per hour 8 colors: 15~25 square meters per hour |

| Number of nozzles | 4 x Epson i3200-A1 |

| Software | neoStampa、Maintop、Photoprint(optional) |

| Printing Accuracy | Default 720x1800 dpi (adjustable up to 720x3600dpi) |

| Device dimensions | 2460mm x 900mm x 1540mm (LWH) |

| Equipment weight | 180KG |

| Printing format | Maximum printing width 1300mm |

| Materials | Art paper, white back / gray back duplex board paper, kraft paper, Tyvek, offset paper, etc,. |

| Material weight | 30~450 grams |

| Ink type | Environmentally friendly water-based pigment ink |

| Image format | PDF/TIFF/JPEG/EFS/PSD |

| Nozzle cleaning | Automatic cleaning |

| Print Interface | Gigabit Ethernet port |

| Power support | AC 220V±10%,50Hz/60Hz |